Seals and gaskets used in the aerospace and aviation industries fill the spaces between mating surfaces on aircraft and commercial vessels. They also provide environmental sealing, oil and fuel resistance, barriers against flame or fire, and other benefits.

Mercer Gasket & Shim is a premier manufacturer of custom gaskets, seals, die-cut parts, and strips. We are an ISO 9001:2015-certified supplier, ensuring that we provide our clients with the right material for their specific industrial applications and mass-production capabilities. In addition, we have a large, modern facility with state-of-the-art equipment and a skilled workforce.

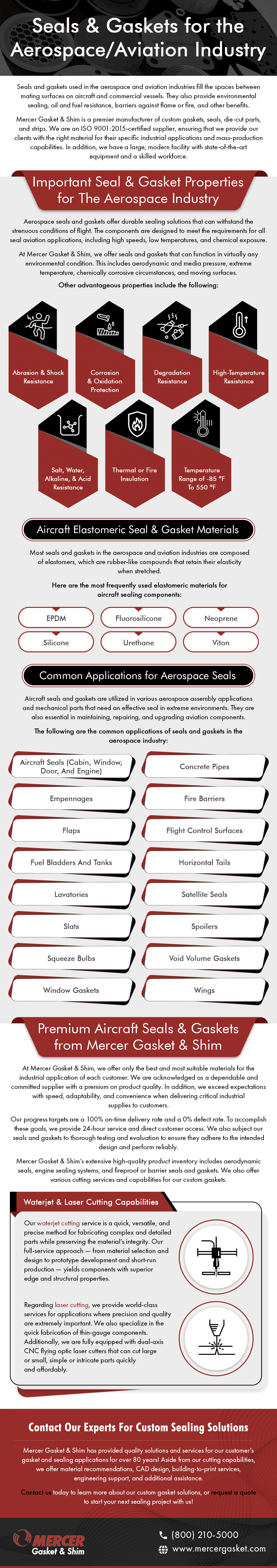

Important Seal and Gasket Properties for the Aerospace Industry

Aerospace seals and gaskets offer durable sealing solutions that can withstand the strenuous conditions of flight. The components are designed to meet the requirements for all seal aviation applications, including high speeds, low temperatures, and chemical exposure.

At Mercer Gasket & Shim, we offer seals and gaskets that can function in virtually any environmental condition. This includes aerodynamic and media pressure, extreme temperature, chemically corrosive circumstances, and moving surfaces. Other advantageous properties include the following:

- Abrasion and shock resistance

- Corrosion and oxidation protection

- Degradation resistance

- High-temperature resistance

- Salt, water, alkaline, and acid resistance

- Thermal or fire insulation

- Temperature range of -85 ºF to 550 ºF

Aircraft Elastomeric Seal and Gasket Materials

Most seals and gaskets in the aerospace and aviation industries are composed of elastomers, which are rubber-like compounds that retain their elasticity when stretched.

Here are the most frequently used elastomeric materials for aircraft sealing components:

- EPDM

- Fluorosilicone

- Neoprene

- Silicone

- Urethane

- Viton

Common Applications for Aerospace Seals

Aircraft seals and gaskets are utilized in various aerospace assembly applications and mechanical parts that need an effective seal in extreme environments. They are also essential in maintaining, repairing, and upgrading aviation components.

The following are the common applications of seals and gaskets in the aerospace industry:

- Aircraft seals (cabin, window, door, and engine)

- Concrete pipes

- Empennages

- Fire barriers

- Flaps

- Flight control surfaces

- Fuel bladders and tanks

- Horizontal tails

- Lavatories

- Satellite seals

- Slats

- Spoilers

- Squeeze bulbs

- Void volume gaskets

- Window gaskets

- Wings

Premium Aircraft Seals and Gaskets From Mercer Gasket & Shim

At Mercer Gasket & Shim, we offer only the best and most suitable materials for the industrial application of each customer. We are acknowledged as a dependable and committed supplier with a premium on product quality. In addition, we exceed expectations with speed, adaptability, and convenience when delivering critical industrial supplies to customers.

Our progress targets are a 100% on-time delivery rate and a 0% defect rate. To accomplish these goals, we provide 24-hour service and direct customer access. We also subject our seals and gaskets to thorough testing and evaluation to ensure they adhere to the intended design and perform reliably.

Mercer Gasket & Shim’s extensive high-quality product inventory includes aerodynamic seals, engine sealing systems, and fireproof or barrier seals and gaskets. We also offer various cutting services and capabilities for our custom gaskets.

Waterjet and Laser Cutting Capabilities

Our waterjet cutting service is a quick, versatile, and precise method for fabricating complex and detailed parts while preserving the material’s integrity. Our full-service approach — from material selection and design to prototype development and short-run production — yields components with superior edge and structural properties.

Regarding laser cutting, we provide world-class services for applications where precision and quality are extremely important. We also specialize in the quick fabrication of thin-gauge components. Additionally, we are fully equipped with dual-axis CNC flying optic laser cutters that can cut large or small, simple or intricate parts quickly and affordably.

Contact Our Experts for Custom Sealing Solutions

Mercer Gasket & Shim has provided quality solutions and services for our customer’s gasket and sealing applications for over 80 years! Aside from our cutting capabilities, we offer material recommendations, CAD design, building-to-print services, engineering support, and additional assistance.

Contact us today to learn more about our custom gasket solutions, or request a quote to start your next sealing project with us!