Flatbed Die Cutting Services

Mercer Gasket & Shim is equipped with new, state-of-the-art flat die cutting equipment. We can assist with mid to high volume mass production runs. Our capabilities include making material recommendations, CAD design, engineering support, and computerized reverse engineering. We have developed a reputation for delivering high-quality solutions with quick turnaround times. As an ISO 9001:2015 certified company, we serve our customers with products and services that undergo strict quality control management.

Contact us, or keep reading to learn more about our Flatbed Die Cutting Services.

Knife Cutting Services

Mercer Gasket & Shim’s highly accurate, state-of-the-art knife cutting capabilities allow us to deliver products to customers when speed, flexibility, and convenience are important. Knife cutting offers a reliable, flexible solution for custom gaskets, depending on the needs of your application. We utilize the newest equipment and take pride in the expertise and training of our staff in the process.

Our digitally controlled equipment allows us to make precise cuts through a diverse range of elastomer, foam, composite, and polymer materials measuring up to 0.50” in thickness. A large 120” x 60” work table enables us to produce large parts rapidly, economically, and with outstanding quality.

Contact us, or keep reading to learn more about our Knife Cutting Services.

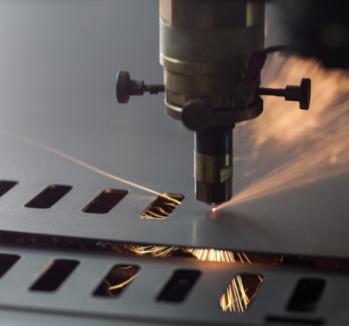

Laser Cutting Services

Mercer Gasket & Shim offers world-class laser cutting services for applications where precision is a high priority and quality is essential. We provide fast turn around when required and offer highly competitive pricing for mass production requirements.

All our production and inspection processes are governed through an ISO 9001:2008 certified quality assurance program and our products meet standards set by leading industrial organizations and government agencies. Our team is flexible, reliable, and dedicated to providing our clients with exceptional product quality and personalized customer service.

Contact us, or keep reading to learn more about our Laser Cutting Services.

Waterjet Cutting Services

Mercer Gasket & Shim’s waterjet cutting service offers a fast, flexible, and accurate method for fabricating complex or difficult parts while maintaining the integrity of the material.

Our ISO 9001:2008-certified processes are executed by technically oriented manufacturing professionals using powerful, high-pressure equipment to produce parts within tight tolerance requirements. From materials selection and part design to prototype development and short run production, our full-service approach provides you with parts that exhibit exceptional edge and structural qualities.

Contact us, or keep reading to learn more about our Waterjet Cutting Services.

Flash Cutting Services

Mercer Gasket & Shim offers highly precise, high speed flash cutting services. Flash cutting aka knife cutting is a highly reliable, tried, and true method of fabrication. Flash cutting is very flexible and can be used to produce prototypes or in very high-volume applications. Mercer Gasket & Shim skilled technicians can assist in material selection and part design when required. Our digitally controlled equipment makes precise cuts through a wide variety of elastomer, foam, composite, and polymer materials measuring up to 0.50” in thickness. We are equipped with a large 120” x 60” worktable enabling the production of large parts rapidly, economically, and with outstanding quality.

Contact us, or keep reading to learn more about our Flash Cutting Services.

CNC Router Cutting Services

Mercer Gasket & Shim is equipped with new, state-of-the-art router cutting equipment. We can assist with mid to high volume mass production runs. Our capabilities include making material recommendations, CAD design, engineering support, and computerized reverse engineering. We have developed a reputation for delivering high-quality solutions with quick turnaround times. As an ISO 9001:2015 certified company, we serve our customers with products and services that undergo strict quality control management.

Contact us, or keep reading to learn more about our CNC ROUTER Cutting Services.

Cutting Services Chart

This informative chart outlines the optimal equipment selections for cutting over 50 distinct materials, along with cutting ranges and tolerances applicable to our equipment. Discover the cutting service that best aligns with your material, application, and volume requirements.

| Mercer Gasket & Shim – Equipment Cutting Specifications | ||||||

|---|---|---|---|---|---|---|

| Waterjet Cutting | Laser Cutting | Flash Cutting | Knife Cutting | Flatbed DieCutting | Router Cutting | |

| Cutting Thickness (Max) | 2″ (50.8 mm) | 0.125″ (3.175 mm) | 0.500″ (12.7 mm) | 0.500″ (12.7 mm) | 2″ (50.8mm) | 5″ (127mm) |

| Cutting Length (Max) | 144″ (3654.6 mm) | 120″ (3048 mm) | 120″ (3048 mm) | 120″ (3048 mm) | 118″ (2997.2 mm) | 120″ (3048mm) |

| Cutting Width (Max) | 144″ (3654.6 mm) | 60″ (1524 mm) | 60″ (1524 mm) | 60″ (1524 mm) | 58″ (1473.2 mm) | 60″ (1524mm) |

| Tolerance (+/-) | 0.007″ (0.1778 mm) | 0.002″ (0.0508 mm) | 0.010″ (0.254 mm) | 0.010″ (0.254 mm) | 0.002″ (0.0508mm) | 0.500″ (12.7mm) |

| Production Volume | High Volume | High volume | Prototype, high Volume, | Prototype, high Volume, | High Volume | High Volume |

Contact us, or keep reading to learn more about which of our Cutting Services is best for each material.

Our Capabilities

Knife Cutting

Mercer Gasket & Shim’s highly accurate, state-of-the-art knife cutting capabilities allow us to deliver products to customers when speed, flexibility, and convenience are important.

Learn More Laser CuttingLaser Cutting

Specializing in fast turnaround of thin-gauge components, Mercer Gasket & Shim offers world-class laser cutting services for applications where precision is a high priority and quality is essential.

Learn More Waterjet CuttingWaterjet Cutting

Mercer Gasket & Shim’s waterjet cutting service offers a fast, flexible, and accurate method for fabricating complex or difficult parts while maintaining the integrity of the material.

Learn More Flatbed Die CuttingFlatbed Die Cutting

Our high-speed, Flatbed die-cutting can be used to create a variety of components, such as gaskets, packaging, bumpers, dampeners, labels, printed products, and more.

Learn More CNC Router CuttingCNC Router Cutting

Mercer Gasket & Shim is equipped with new, state-of-the-art router cutting equipment. We can assist with mid to high volume mass production runs.

Learn More